Imagine a problem with a connector breaking off the board. Usually, this is not a big deal but worst case – a couple of torn traces and a new connector – unless, of course, we are talking about the reef gear. In which case, we have to expect things breaking in new and unusual ways!

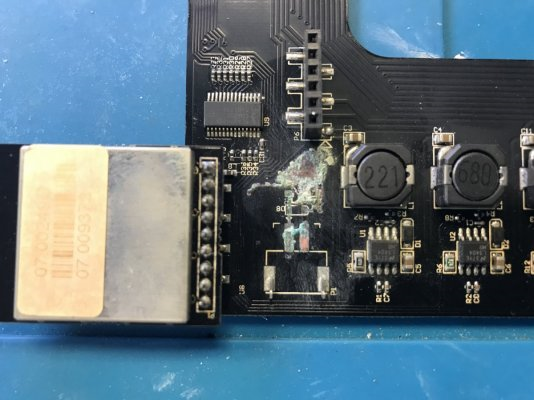

This is certainly the case with this AI Hydra light. This was also a mail in service request from a fellow reefer. So, I am not exactly sure how this connector came off the board, but… well, take a look at this.

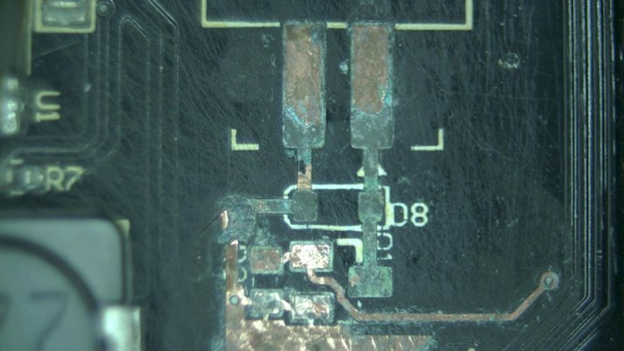

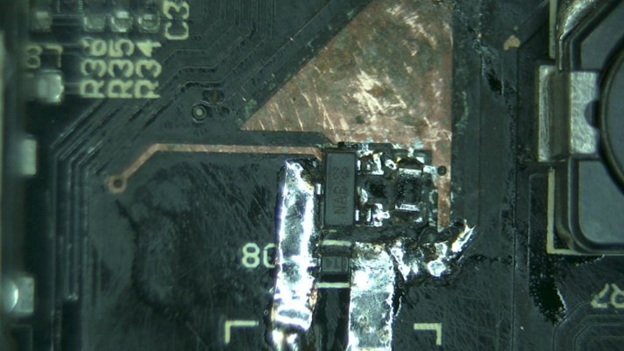

What??? The entire fan circuit is missing. Every. Single. Component.

The area is covered in a thick layer of corrosion to the point you can not tell what is what.

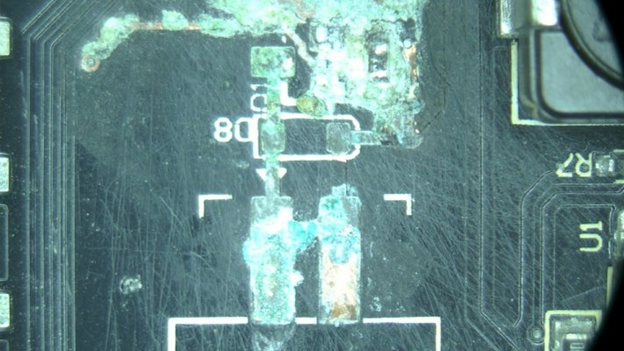

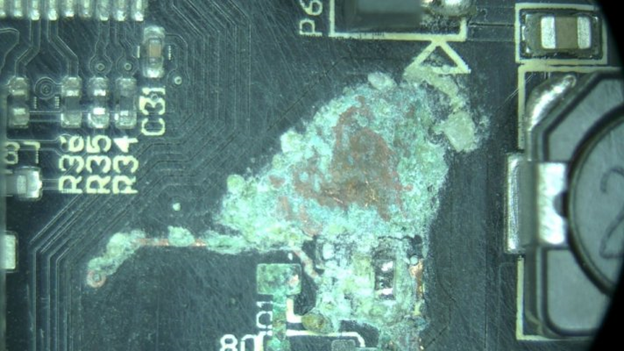

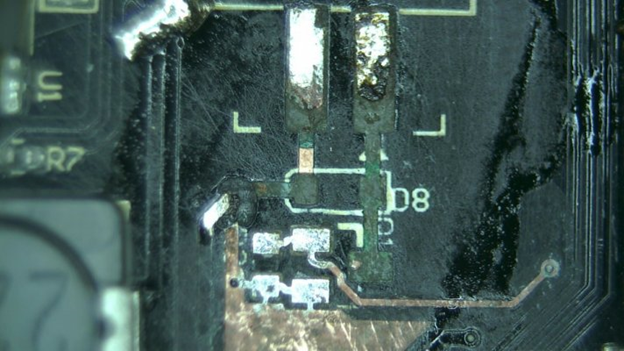

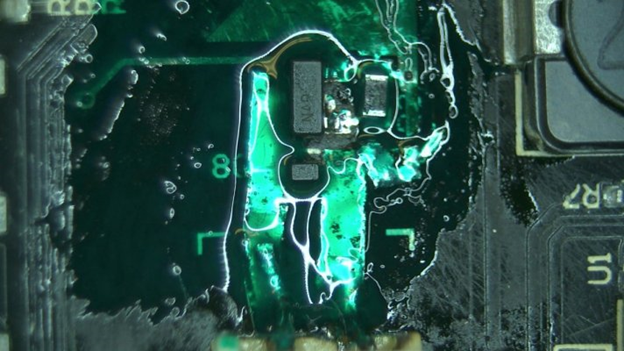

Let us clean up the corrosion and see if there is anything left below it.

Now, it is clear that at least some traces and pads corroded away entirely. Both pads from the connector are no longer connected to the board circuit. It looks like there should be a diode, a resistor and some other component.

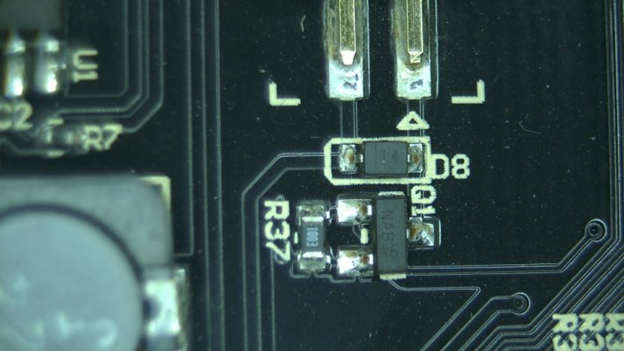

This is what the fan control circuit should look like.

The third missing component turns out to be a small MOSFET. This makes sense because something needs to help the controller switch the fan on and off after all.

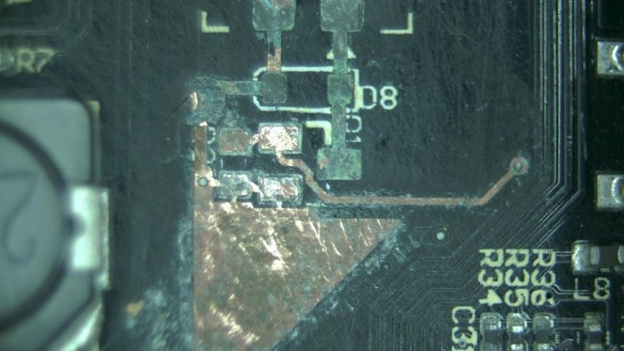

Let us get started on restoring the board traces. This time, instead of using the jumpers, I decided to use copper to lay out the new traces.

As you can see, it is not all that bad. Just a couple of runs from the connector pads to link them to the diode and the MOSFET, while carefully avoiding unrelated traces in close proximity. Anyway, we are ready to layout the missing components.

At this point, the fan should work once plugged in. But all of this exposed copper will corrode very quickly again and then the corrosion will push the new components off the board again. To solve this, I will put a good layer of conformal coating over the entire area.

This coating needs to be cured to harden it.

Once hardened, the conformal coating not only protects against corrosion, but also helps to hold my traces to the board.

Now it is time to test if the new fan circuit actually works.

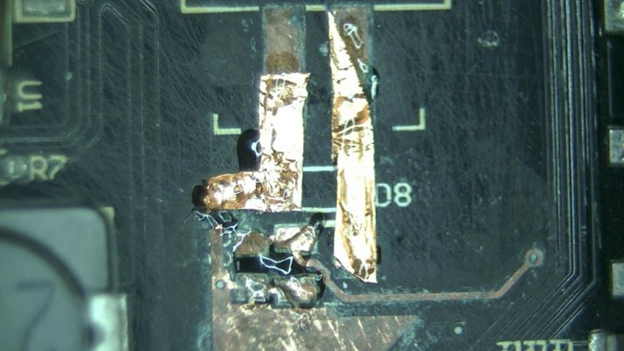

My leading theory on why the damage to the board was so significant that it was a sequence of events with the old fan failing and shorting first. The short caused a part of the circuit to burn out. You can actually see a small hole in the board right next to the diode where a part of the trace used to be. The short on the board made the black coating to flake off exposing copper on several traces. Copper usually corrodes violently, which might have been enough to push all the circuit components off the board.

Either way, the light is now working and the board circuit is corrosion resistant.

We can make your AI Hydra work again. Head over to the Mail-In Repair section to find out how to send us your device for repair.